Innovation for Cutting Performance

Innovation for Cutting Performance

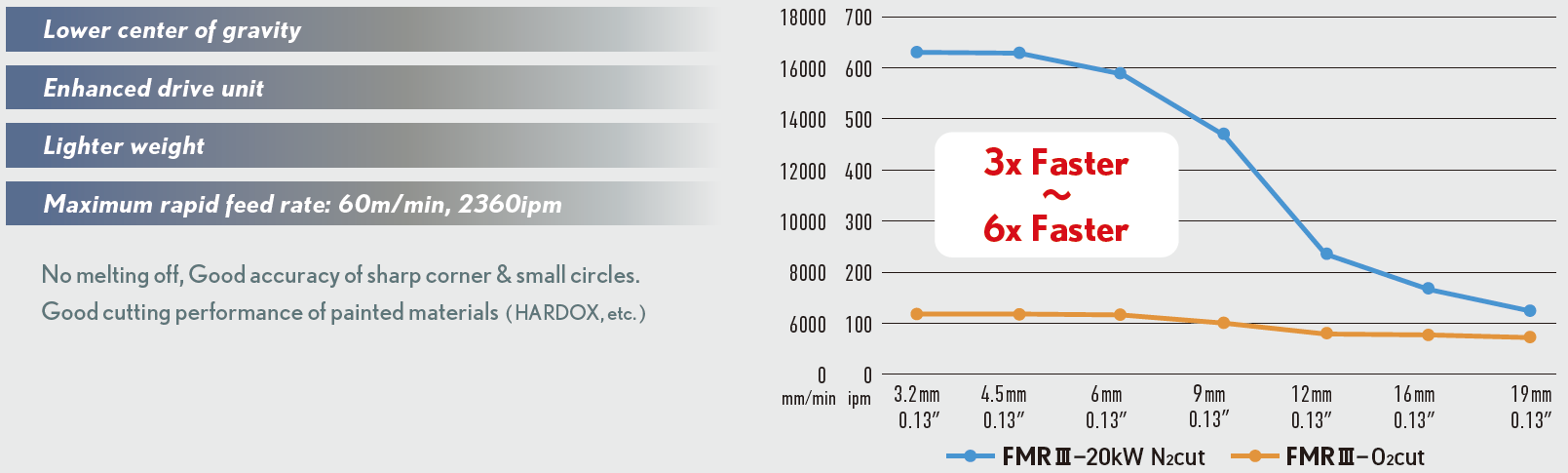

The new design achieves faster nitrogen cutting and transverses higher speeds by lowering the machine's center of gravity and decreasing the machine's weight. This design change from its predecessor provides for a superior cutting performance. this is a completely new fiber laser cutting machine from TANAKA!!

NEW & DISTINCT OPERATION DESIGN

NEW & DISTINCT OPERATION DESIGN

Excellent Operability

Cockpit design with a slim operation panel / New operation screen & Intuitive operation

Improved Maintainability

Slid door for easy maintenance / Quick access to torch head from operation deck

Installed automatic lubrication systems

TANAKA CUTTING SIGNATURE

TANAKA CUTTING SIGNATURE

High-Speed Cutting & Performance

Offers faster cutting than CO2 laser cutting machine / Great performances for rusty mild steels

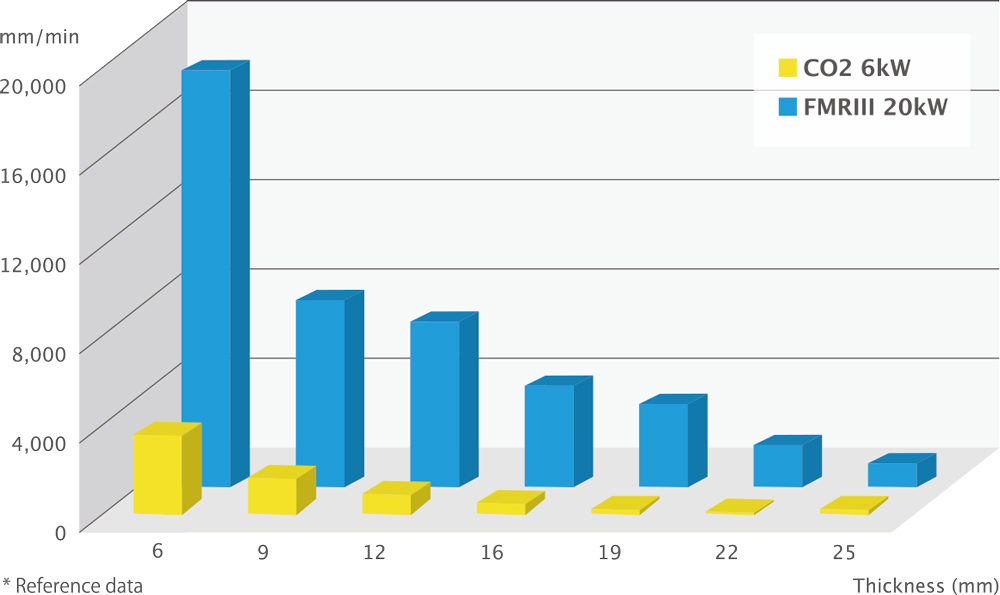

- Mild Steel Cutting Speed -

.jpg?1038) - Stainless Steel Cutting Speed (N2 Cutting) -

- Stainless Steel Cutting Speed (N2 Cutting) -

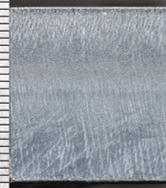

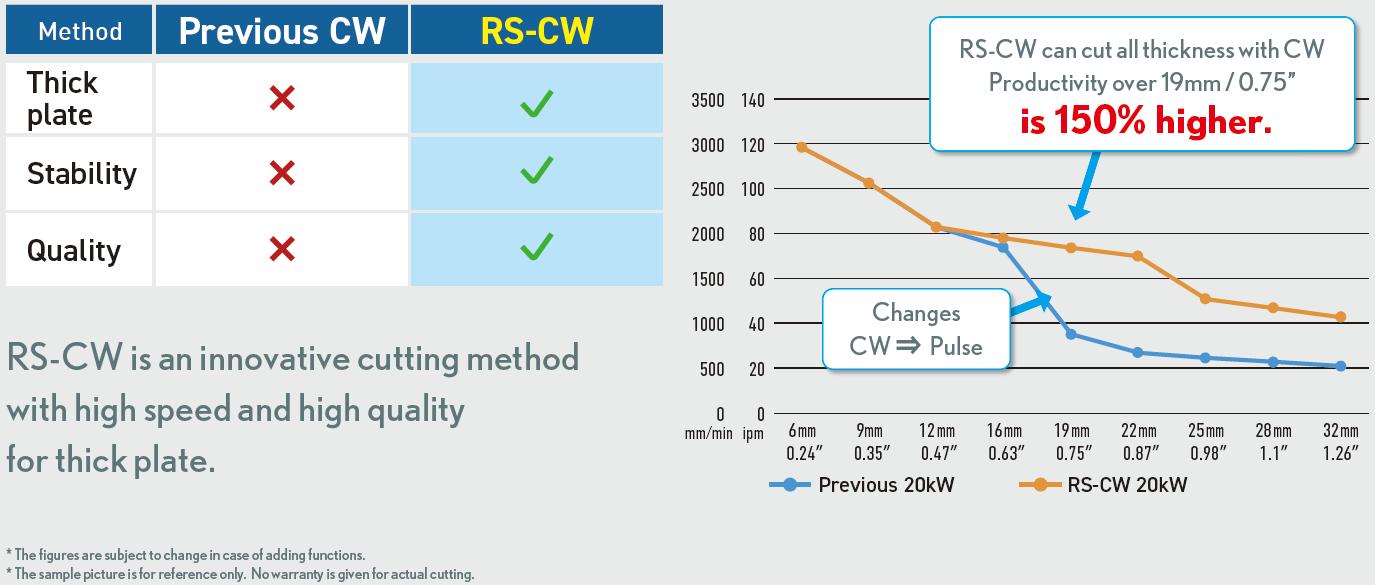

Advantages of RS*-CW Cutting (*RS: Range-Spread)

Cutting without Burning!

- Superior cutting edge quality

- Expanded maximum cutting thickness / FMRIII-20kW: Mild steel SS400 Max. t40mm (1.57")

- Improved cutting stability for rusty surface

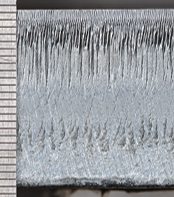

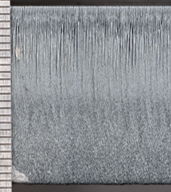

Rusty Mild Steel SS400 t25mm (1")

RS-CW has much better cutting quality than previous CW cutting

| Thickness 25mm / 1" |

Previous CW |

Pulse |

RS-CW |

| Feed rate |

1,100 mm/min 43 ipm |

650 mm/min 25 ipm |

1,300 mm/min 43 ipm |

| Cutting surface |

|

|

|

| Max. cut surface |

Ave. of 10 points

116.4 μm 4582.7 μin |

Ave. of 10 points

56.2 μm 2212.6 μin |

Ave. of 10 points

35.5 μm 1397.6 μin |

| Cutting surface dent |

0.09 mm 0.003" |

0.06 mm 0.002" |

< 0.04 mm < 0.015" |

| Cutting surface angle |

-1.0 degrees |

-1.2 degrees |

-0.1 degrees |

All thicknesses can be cut CW - Significant increase in productivity

New Mild steel N2 Cutting

High-speed Mild steel N2 cutting with a large gantry machine

New Mild steel N2 Cutting

High-speed Mild steel N2 cutting with a large gantry machine

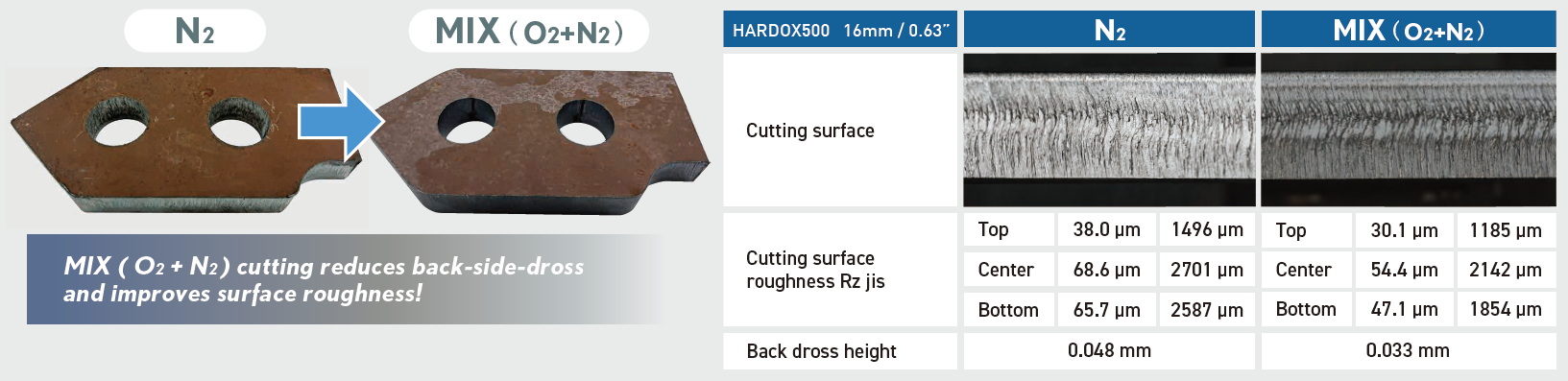

MIX cutting reduce dross.

MIX cutting reduce dross.

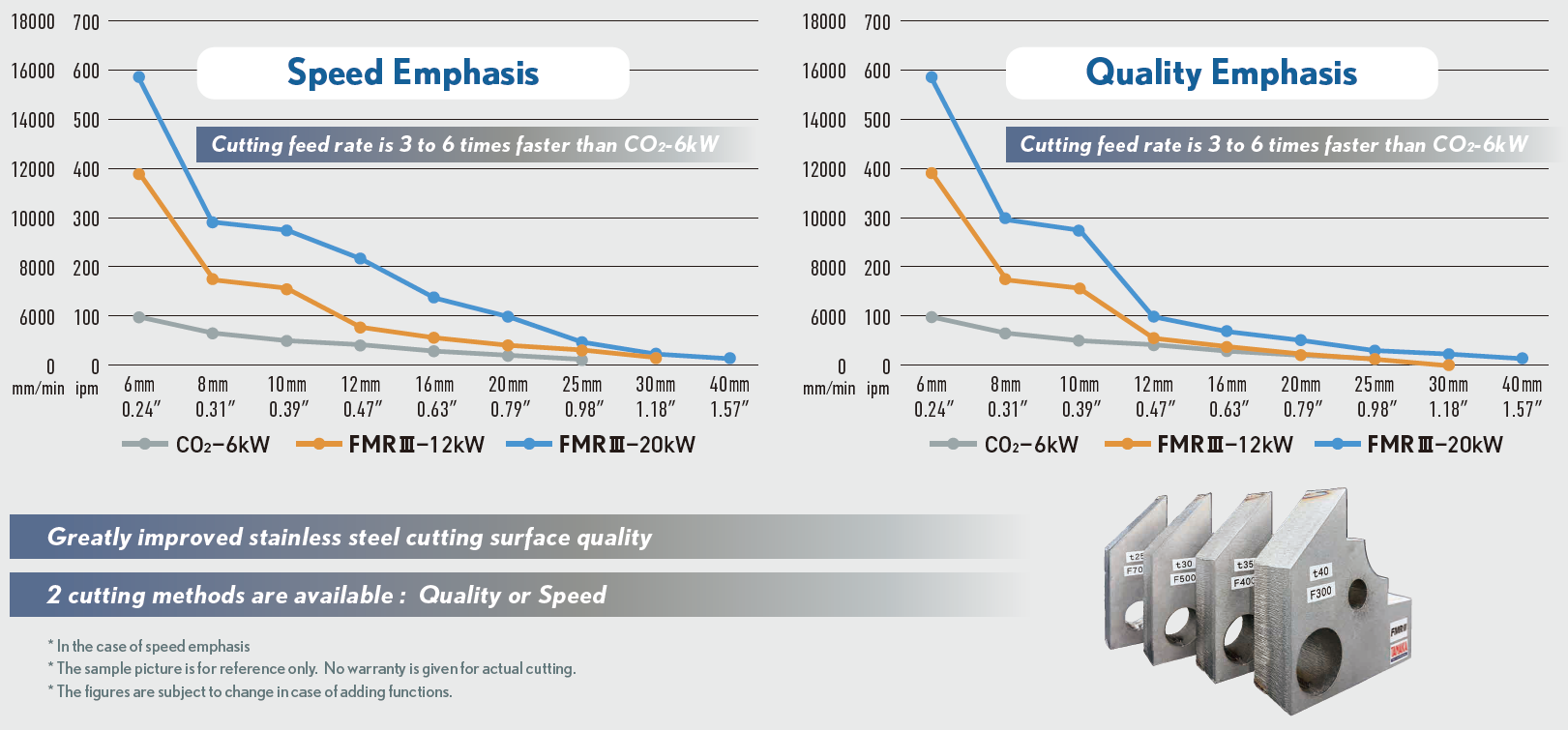

New Stainless steel N2 Cutting

New beam mode: Greatly improved quality & cutting feed rate on stainless steel cuts

New Stainless steel N2 Cutting

New beam mode: Greatly improved quality & cutting feed rate on stainless steel cuts

■Machine specification

| Model |

25 |

30 |

35 |

40 |

45 |

50 |

55 |

Effective cutting width

mm(feet) |

2,600(8.5') |

3,100(10.1') |

3,600(11.8') |

4,100(13.4') |

4,600(13.4') |

5,100(16.7') |

5,600(18.3') |

Rail span

mm(feet) |

3,500

(11.4') |

3,800

(12.4') |

4,000

(13.1') |

4,300

(14.1') |

4,500

(14.7') |

4,800

(15.7') |

5,000

(16.7') |

5,300

(17.3') |

5,500

(18.0') |

5,800

(19.0') |

6,000

(19.6') |

6,500

(21.3') |

6,500

(21.3') |

7,000

(22.9') |

Total length of machine

mm(feet) |

4,700(15.4') |

5,200(17.1') |

5,700(18.7') |

6,200(20.3') |

6,700(22.0') |

7,400(24.3') |

7,900(25.9) |

Effective cutting length

mm(feet) |

Rail length - 3,200 (10.5')* |

| NC device |

FANUC 0i-LF Plus |

*Rail length can be extendable as per 1,200m(3.9').

<Additional rail length shortening> i-marking device(OP): -200mm(0.66') / Mounting oscillator on machine(OP): -850mm(2.8')

■Speed specification

| Processing feed speed (inch) |

1 ~ 24,000mm/min (0.03 ~ 944ipm) |

| Hi-Rapid feed speed (inch) |

60,000mm/min (2,362ipm) |

| Rapid feed speed (inch) |

36,000mm/min(1,417ipm) |

| Manual rapid feed speed (inch) |

24,000mm/min (944ipm) |

| Cutting head up / down speed (inch) |

20,000 / 15,000mm/min (787 / 590ipm) |

| Home return speed (inch) |

24,000mm/min (944ipm) |

| i-Marking speed (inch) |

24,000mm/min (944ipm) |

■Standard cutting specification

| Model |

TI12000 |

TI20000 |

| Mild steel |

28mm (32mm)* / 1.1" (1.57")* |

40mm / 1.57" |

| Stainless steel |

30mm / 1.18" |

40mm / 1.57" |

| Aluminum |

30mm / 1.18" |

40mm / 1.57" |

Under validation: Cutting quality and Dross adhesion may vary depending on material, thickness and condition.

* Figures in parentheses are not guaranteed at product cutting.

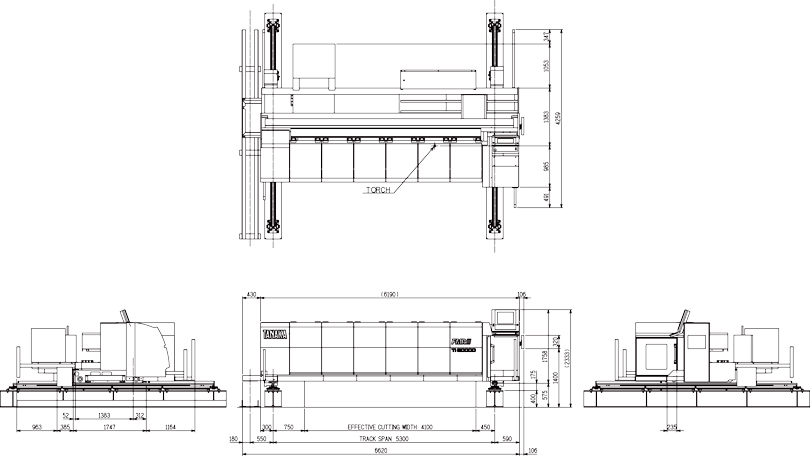

■FMRIII40-TI20000

*The figures are subject to change in case of adding functions.

*The figures are subject to change in case of adding functions.